Electrical Safety: Electrical shock is the 2nd highest cause of industrial fatality. Almost thousands of people meet with an accident with electricity out of which 60% got dead due to electrical shocks so it is very important to take extra precautions while working on or near to electricity.

Electricity is a major contributor to industrial fire. In flammable chemical industries failure of electrical equipment generate sparks (Heat) that work as an ignition source for fire and resulted in a major fire or explosion. Short-circuit in an electrical line is also one of the reasons behind some fires. The use of industrial vehicles (i.e cranes, Hydra, MEWP, boom lifter, etc.) increased in the last few years and it witnessed many accidents while it touches overhead powerlines during movement or operations

In a residential fire, almost 80% of the fire is just because of a failure of electrical equipment or overloading of electrical power sources. In this type of fire, people lost their entire life earnings and overall billions of dollars vanished just because of a lack of awareness about electrical safety. All of the above conditions are easily avoided if appropriate electrical safety precautions are taken place.

This article on electrical safety covers details of

Table of Contents

Basics of Electrical Power

Electrical power travels through the insulated conductors from one place to another place. Conductors are wrapped in nonconductive materials such as rubber, plastics, ceramic, and glass to avoid direct contact with the conductor while the current is flowing from them. Sometimes these insulations of cable got damaged due to long working cycle, expiry of insulated materials, overload of current, or contact with a sharp object and resulting in electrical shocks and fire

To avoid electrical shock grounding of electrical equipment is required. Grounding creates a low resistance path which helps in protection against shock. In general, the supply of all electrical apparatus is taken through three-prong plugs and the use of ELCB or RCBO helps to save from electrical shocks.

Apart from these different types of relays and protection are used in electrical circuits to protect against overload, earth leakage, short-circuit current, etc.

Let’s understand the hazards of Electricity which is important to understand electrical safety

Types of Electrical Hazards

In electricity, there are mainly five types of hazards involved

- Electrical Shock (Electrocution)

- Electrical Burns

- Arc Flash & Arc Blast

- Electrical Fire and Explosion

- Secondary Hazard

Electrical Hazard impacted highly on the human body, so it is very important to understand each of these hazards in detail to avoid accidents

1. Electrical Shock (Electrocution)

Electrical shock happens once an individual touches a live surface and a current pass through their body using the body as a conductor. Unexpected contact with electricity is a major concern in industries, power distribution companies, warehouses, offices, and even at homes which resulted in fatalities or serious injuries.

Electrical shock and electrocution are often misused terms.

Electrical shock can be harmful to the body, electrocution is the term for a fatal electrical shock.

The effects of electrical shock

| Current | Effects |

| < 1 mA | None |

| 1 mA | Perception threshold |

| 1-3 mA | Mild sensation |

| 3-10 mA | Painful sensation |

| 10 mA | Paralysis threshold of arms. Cannot release handgrip |

| 30 mA | Respiratory paralysis (stoppage of breathing) |

| 75 mA | Fibrillation threshold. May produce a 0.5% uncoordinated heart action |

| 250 mA | Fibrillation threshold. May produce a 99.5% uncoordinated heart action |

| 4 A | Heart paralysis threshold. For the duration of the current passes the heart stops. May restart when current stops |

| > 5 A | Tissue burning. Generally not fatal unless vital, organs are burned |

The Severity of electrical shock depends on

- Voltage: Higher the voltage, Greater the current

- Duration: The length of time that person is exposed to electricity (i.e. 60ma for 30milliseconds is unlike to cause severe injury, where 60ma for 2 sec may cause fatal)

- Current Path: The route the electricity takes through the body (i.e. if it runs through the chest it affects the heart)

- Frequency: Frequency of Ac Current

- Resistance: Skin condition -lower resistance higher current dry skin has resistance 100000 ohm but wet or damaged skin has 1000 ohm

- Contact Surface Area: The more skin that is in contact with the live surface, the lower the resistance and more severe the injury

- Environment factors: Any environment factors that reduce resistance will increase the current flow and increase the severity of shock i.e.Metal Surface, humidity, wet surface, etc.

Understanding of Severity of electrical shock is required to develop control measures for electrical safety

Do you know 50V is enough to kill humans?

The resistance across the human body when an adult touches two hands on a metal conduit is around 1,500 Ohms. If there is a potential difference of around 50 V across the body, then approximately 30 milliamps of current would flow.

As per the effects of the electric shock, 30 ma is enough to stoppage of breathing, this is the reason that all electrical safety devices (i.e. ELCB, RCBO) require a protection level of 30ma.

Common causes of electrical shocks

- Failure of electrical equipment

- Damages of insulations

- Working with poorly maintained equipment

- Selection of wrong tools (Noninsulated, damaged)

- Working with live electrical power

- Contact with overhead powerlines

- Using Electrical apparatus in the hazardous atmosphere such as humid, flammable, wet, or explosive atmospheres

- Power supply without plug top lose wiring

- Unauthorized working

- Electrical joints in cables

- Cable damage during excavation work

2. Electrical Burns

During Electrical accidents people received burns in two different ways

- Direct Electrical Burns

- Indirect Electrical Burns

Direct electrical burns:

When anyone touches a live electrical conductor and current passes through their body at that time current creates heating in the skin. This heating creates burns at the entry and exit of the skin. If it burns internal tissue it may result in fatal

Indirect electrical burns:

This kind of burn does not occur due to current passing through the body, but it occurred due to the radiant heat of arc flashes during electrical accidents. In these types of burns, severity depends on how much a person is exposed to arc flashes

Common causes of electrical burns

- Working on the live electrical supply

- Damages to cable insulation

- Unknown to the risk of electricity (lack of awareness)

- Working near overhead conductors

- Arc flash boundary not defined

- Not using arc flash suits according to arc flash study

- Failure of electrical equipment

- Inadequate electrical protections (relay, ELCB, etc.)

3. Arc Flash & Arc Blast

Arc Flash

Electrical Arc Flash is one of the high-risk hazards associated with Electricity

An Arc Flash is an energy discharge of light and heat generated during an electrical fault in the energized circuit. The arcing results in a release of a tremendous amount of energy as the current flow through ionized air.

The typical electrical arc produces a temperature of around 35,500 °F or 20,000 °C. That is 4 times the temperature of the surface of the sun. The size of the arc is mainly determined by the short circuit fault current available and the time that it takes to “trip” the up-stream over-current protection device

Burn body parts due to Arc Flash:

- Severe burns may occur if the skin receives more than 1.2 calories/cm2 of thermal energy for more than 100 milliseconds.

- Severe burns may occur if the skin temperature is greater than 210 °C for more than 100 milliseconds.

Every year over 100,000 people in the world were brought to hospitals with severe electric arc flash burns and the average cost for each of these burn victims was over 1 million US dollars.

Arc Blast

Arc Blast is a supersonic shockwave produced when the uncontrolled arc vaporizes the metal conductors. Arc Blast is the explosive energy of an arc flash

In many cases, during working in electrical panels the arc flash event begins with a screwdriver making a phase-to-ground contact within the disconnect switch. Once the arcing begins, all 3 phases of the circuit become involved causing the arc blast to escalate.

Electrical Fire: Electrical devices expand 67,000 times their normal size when it converts into a plasma fireball at 35,500 °F or 20,000 °C. This explosive force is roughly equivalent to the detonation properties of TNT. This resulted in the fire in the electrical equipment

Shrapnel: The molten metal and shrapnel from the electrical equipment may travel at 700 mph.

Hearing loss: The sound wave produced by an arc blast is excessive and can exceed 160 decibels. The threshold for pain is 140 decibels. An arc blast can cause permanent damage to your hearing, That is why hearing protection is mandatory while working on electricity

Air Expansion impact on the human body: A pressure wave from an arc blast strikes the body causing both external and internal injuries. External injuries happened due to being thrown or knocked down by the force. Internal injuries can collapse lungs and damage other organs. Internal symptoms may appear long after the initial injury.

Burns: Savior burns can occur even when a worker standing 10 feet away from the arc due to the discharge of high energy at a time at high pressure which travels long distances. This is the reason that arc flash suits are required in the electrical panel room

Vision loss: At the time of Arc blast high-intensity lights produce and our eyes are not suitable to see such kinds of high-intensity lights which may result in damage to eyes sites. Due to this concern, it is recommended to use appropriate goggles while working near electricity

Overheated electrical conductors or equipment can cause fire or explosion while contact with flammable liquids, vapor or combustible dust, or combustible material

Common causes of arc flash & arc blast

- Working on exposed live electrical parts

- Sudden drop of tools or material on live parts

- The poor condition of test equipment

- Poor maintenance of circuit protection

- Overloading of supply boards or underrated cables

- Inadequate safety protection

- Wrong operation mainly in Power panels

- Wrong selection of electrical Panels i.e. Humid atmosphere & No IP protections

- Accumulation of a dust particle in Electrical panels

- Electrical panel cleaning in live supply

- Short circuit due to reptile entry in live panels & touches two phases

- Unauthorized working

4. Electrical Fire and Explosion

Electrical fire is the most common type of fire observed in industries, offices, or at home. Inadequate protections lead to an electrical fire. Due to inadequate protection apparatus got overheated or the circuit got short which works as an ignition source for fire.

Common causes of electrical fire and explosion

- The system may be overloaded so more current passes the maximum design capacity of equipment which creates heating

- Faulty electrical equipment got overheated and resulted in a fire

- Misuse of equipment i.e. it may be connected to the main supply by pushing the bare wire in to socket rather than using the proper plug

- Presence of a flammable atmosphere that ignites by electricity. This can happen in two different sets of circumstances

- Wrong types of electrical equipment selection (use of non flameproof equipment in the flameproof area)

- A flammable atmosphere is accidentally created in an area where it would not be expected

- Electrical equipment may produce heat or sparks as a part of its normal operation. If it is poorly positioned next to a flammable material it may start a fire.

- Poor internal connection. Poorly internal connection increase resistance which leads to overheating at the connection point

- Continue running of electrical equipment without preventive maintenance

- Static electricity is also one of the reasons for many accidents

5. Secondary Effects

The secondary effects are types of injury resulting indirectly from receiving an electrical shock. Common secondary effect injury occurs when people go under violent muscle contractions during electrical shock. i.e. person working at a height and receiving a shock at that time he falls from height and as a result of the fall he got cut, bruises, and broken bones. This injury occurred not because of shock but due to a fall so it’s called secondary effects

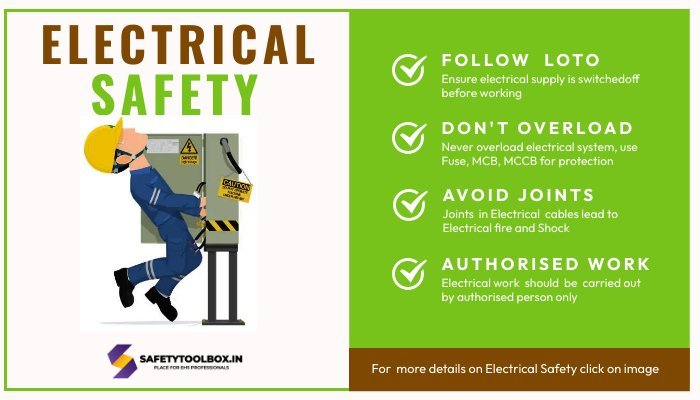

Electrical Safety Control Measures

To overcome electrical safety hazards follow the below electrical safety measures

- Strictly Follow energy isolation (LOTO) before working on any electrical equipment, circuits

- Before using any electrical equipment ensure its conditions ok or not

- Avoid working in live electrical panels, machines, or equipment unless you are trained and competent to work in it

- Define arc flash boundary for each panel and maintain safe distance as per boundary

- Before working ensure the conditions of testing tools must be double insulated (i.e. tester, multimeter, etc.)

- While working near flammable material always use flameproof tools

- If observed any smells, sparks, or shock in any equipment turn it off and don’t use it

- Always use a three-prong plug or industrial plug in place of two prong plug

- Provide appropriate earthing on equipment with metal body

- Always use prong plug despite loose connection in sockets

- Ensure use of appropriate cord according to the machine’s current carrying capacity

- Replace the damaged cord immediately. Don’t use insulation tap

- Don’t keep the bare wire in the workplace

- Don’t lay the cable from the area of vehicle movement, if required ensure the use of appropriate mechanical protection (conduit)

- Don’t lay the extension cable from the chemicals storage area

- Don’t lay cable nearer to sharp edges

- Avoid joints in electrical cables

- Don’t use damaged power tools

- Avoid the use of power tools in wet, humid areas

- Always make connections of power tools through ELCB, RCBO

- Use double insulated power tools

- Consider the use of battery-operated power tools

- Don’t use the cord to raise or lower equipment, tools

- Don’t reach blindly into space that may contain energized equipment

- Provide double body earth to all electrical panels

- Installed electrical tested insulated rubber mates in Infront of electrical panels

- Provide appropriate canopy on outdoor electrical panels and ensure appropriate IP rating for outdoor panels

- Don’t wear metal jewelry or ring while working around electricity

- Don’t touch electrical equipment with a wet hand

- Use a nonconductive ladder (i.e. FRP) while working with an electrical supply

- Ensure appropriate protection available to save against overload current i.e. fuse, MCB in all machinery

- Avoid overloading of portable electrical extension boards

- Keep electrical panel rooms free from unwanted material to avoid the source of fire

- Before working on high voltage (switchyard) make sure all phases are de-energized with discharge rod

- Always maintain a safe distance with an overhead power line. Install goal posts at places where risk of intervention with overhead line

- Before excavation work ensures no energized cable passes through the excavation area

- Place route marker on underground cable to identify cable route in future

- Place appropriate signages on electrical panels (i.e., flash hazard, a danger sign, etc.)

- Ensure the entire electrical team must be trained on first aid measures for electrical shock

- Installed smoke detectors on all electrical panels to identify any fire

- Always keep the supply of electrical equipment in off condition while not in use

- Don’t play with electrical equipment

- Use electrically tested hand gloves while working on live electrical components according to source voltage

- Use Arc flash suit according to arc flash study while working on electrical panels

Always keep top priority to electrical safety at your workplace to save humanity & save the nation

For more articles on safety please click here…

For regular updates of our article please do follow us on linkdin by clicking here

very nice

What is the meaning of 32cl, 40 cl and other number in arc flash suite,

And how to identify according to voltage suitable arc flash suite…

Cl means calories. Based on arc flash study you can select cl value of arc flash suite